OTHER MILL MODS

- Backward Laser Engravings as of year 2001

- Parallel Leadscrew

- Z-Axis Leadscrew

Handles

Date: 1-28-01

I decided to lighten my wheels and give them a fancy look! I first turned them thinner and mounted them on the rotary table. Divide 360 degrees by the number of holes you want and that's it! Turn the table, drill, turn the table, drill! Wa-La, beautiful handles! After mounting them, I found the machine would vibrate when the handles would spin.

I STRONGLY suggest that you balance the handles for CNC use. I would also remove the "little handles" off the wheels for safety and balance.

I STRONGLY suggest that you balance the handles for CNC use. I would also remove the "little handles" off the wheels for safety and balance.

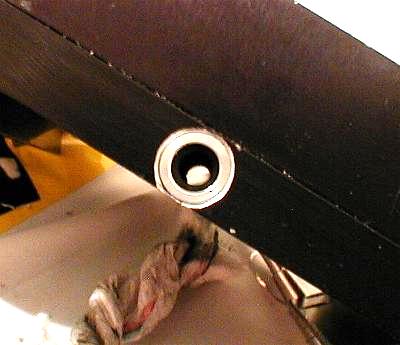

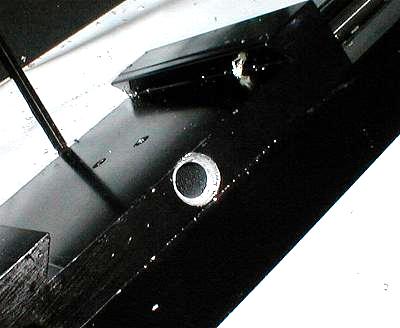

Wiper

By far one of the most things I dislike about the the Sherline mill is the lack of leadscrew covers to protect the Y-axis. For now, I have added leadscrew wipers to keep the chips out of the nut and inside the Y-axis base. This is a spin off of Sherline tip# 17, thanks Larry (click HERE to see many other great Sherline tips too). Reason it's modified is to prevent the loss of any axis travel.